Our proprietary "valve gate systems" offer superior durability, maintainability, and safety.

Cylinders are used to mechanically open and close valve pins inserted in the gate bushing to achieve optimal resin flow control.

We create various valve gate systems in different forms for different applications.

- We also sell stand-alone controllers for customers who do not have a valve gate controller.

- By leveraging our position as a mold manufacturer, we can provide comprehensive support, from design and assembly to handling and after-sales service.

We are also able to respond rapidly to specification changes and repairs.

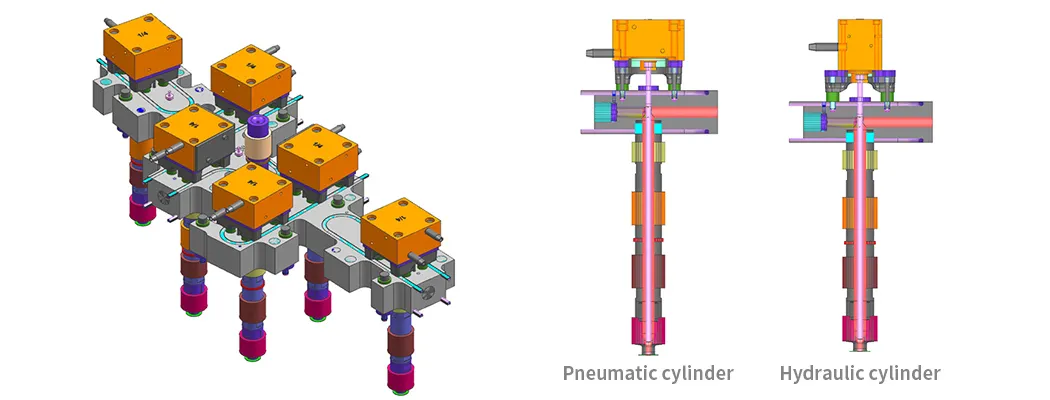

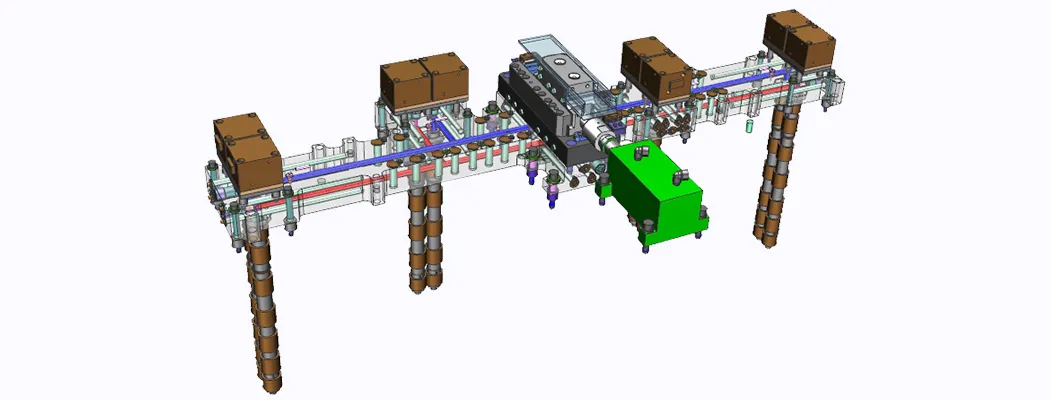

STANDARD

Valve gate system features

-

Eliminates resin stringing from gate

-

Enhanced formability and fluidity (flow control)

-

Simple structural design offers high durability

-

Monolithic structure enables easy maintenance

-

High precision parts ensure reliable operation

Frequently asked questions

- What are the features of S-VANCE valve gates?

-

For customers using open gates, this product can help eliminate weld lines and improve formability because it eliminates stringing issues and enables flow adjustment.

Our valve gates also feature high precision parts and simple structures, leading to high durability.

The manifold block and nozzle are integrated into a single unit for high maintainability.

As is the case in the majority of modern systems, the nozzle parts are screwed in and fixed in place, eliminating the risk of resin leakage. - What types of S-VANCE valve gates are available?

-

We provide valve gate systems to meet a variety of needs.

We develop all our VGs in-house, including standard VGs suitable for large molds such as bumpers, instrument panels, and door trims; small VGs suitable for small molds; VGs for innovative molding machines; twin-way VGs that allow for color changes in 1 shot; and electric VGs that allow for fine valve control. - What types of valve gate opening/closing systems are available?

-

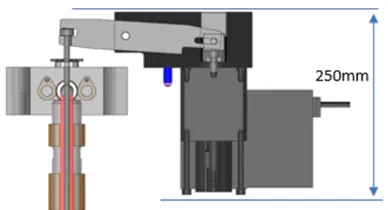

In addition to conventional hydraulic and pneumatic cylinder VGs, we also offer motor VGs driven by an electric motor and gear unit.

In addition to typical direct press VGs, in which the cylinder is placed on top of the manifold block, we also offer cam-type VGs, which are effective in reducing mold thickness and weight. - Are the cylinders equipped with a cooling system?

-

Our hydraulic and pneumatic cylinders have heat-resistant structures and do not require cooling circuits.

Since there is no need to install extraneous cooling circuits, they are low-cost and energy-efficient.

The same applies to our electric and cam-type VGs. - Are the cylinders equipped with Limit Switch for verifying their operational status?

-

You can select between cylinders with limit switches and cylinders without limit switches depending on your requirements.

The limit switches are proximity sensor switches and are heat resistant, same as cylinders.

In general, 2 limit switches — open (OP)/closed (CL) are installed on a single cylinder, but they can also be set to either open (OP) or closed (CL) only upon customer request. - What is the type of heater used in the manifold block?

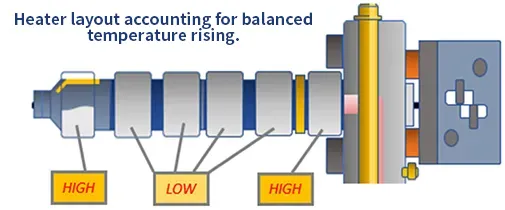

-

Since many automakers have adopted our products, we offer a wide variety of heater types.

We offer horizontal cartridge heaters that are placed along the resin flow channel, vertical cartridge heaters that are placed alongside heaters of the same size, and sheath heaters, which are rod-shaped heaters that fit into grooves dug into the manifold block. Each of these heater types have their own advantages. - What is the type of heater used in the nozzle part?

-

Band heaters are available as standard for easy customization and maintenance.

- Are different types of sensors (thermocouples) available?

-

You can choose between J (IC) and K (CA) type thermocouples.

They are available in screw, band, and sheath types for manifold blocks and nozzle parts.

They can be installed to offer control at optimal temperature balances. - Can temperature control panels be used with general purpose machines?

-

Temperature control panels can be used with general purpose machines without any problems. (only electric valves require a dedicated controller)

We also manufacturer highly customizable valve gate controllers, so please contact us for more information.

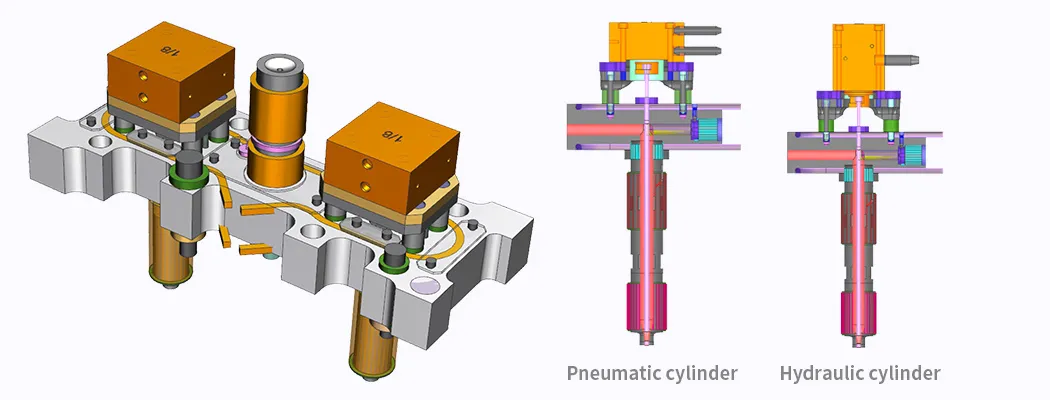

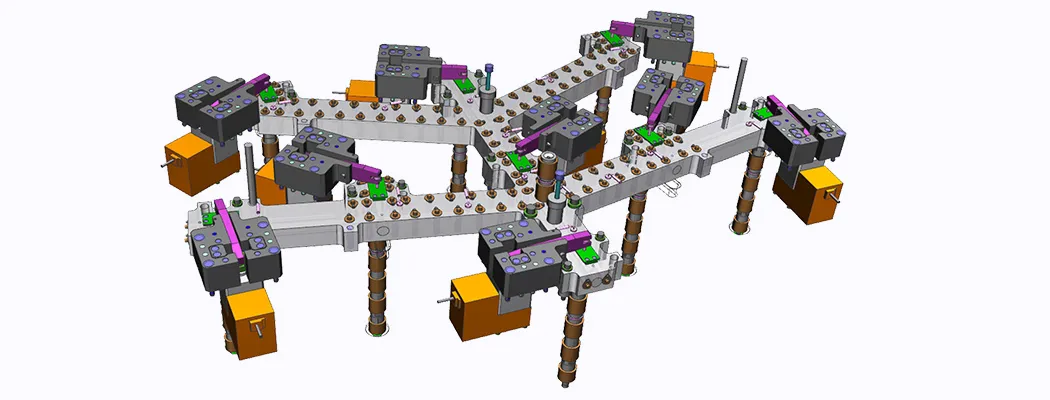

SMALL COMPACT

Recommended for less than 850 Ton press Injectionmachine.

-

Compact size suitable for small (thin) molds

-

Flexible heaters for easy bending and replacement

-

Ring heaters for temperature balance

-

Improved moldability, flowability, and temperature balance

-

Monolithic structure enables easy maintenance

-

High precision parts ensure reliable operation

Frequently asked questions

- What are the criteria for choosing between standard VGs and small VGs?

-

In general, injection machines can be roughly divided into less than 850 Ton press and those more than 850 Ton press. We recommend standard VGs for using injetion machine more than 850 Ton press, and small VGs for using injection machine less than 850 Ton press.

The choice of VG also depends on the usage conditions, so feel free contact us for a consultation. - What types of valve gate opening/closing systems are available for small-type valve gates?

-

Same as standard VGs, pneumatic/hydraulic cylinders are available.

We also offer motor VGs driven by a small electric motor and gear unit. - Are small-type valve gates also equipped with Limit Switch for verifying the operational status of the cylinders?

-

You can select between cylinders with Limit Switches and cylinders without Limit Switches depending on your requirements.

The Limit Switches are proximity sensor switches and are heat resistant, same as the cylinders. - What is the type of heater used in the manifold block?

-

Sheath type heaters, which are rod-shaped heaters that fit into grooves dug into the manifold block, are used.

- What is the type of heater used in the nozzle part for small-type valve gates?

-

Space-saving, high-wattage compatible ring heaters are used.

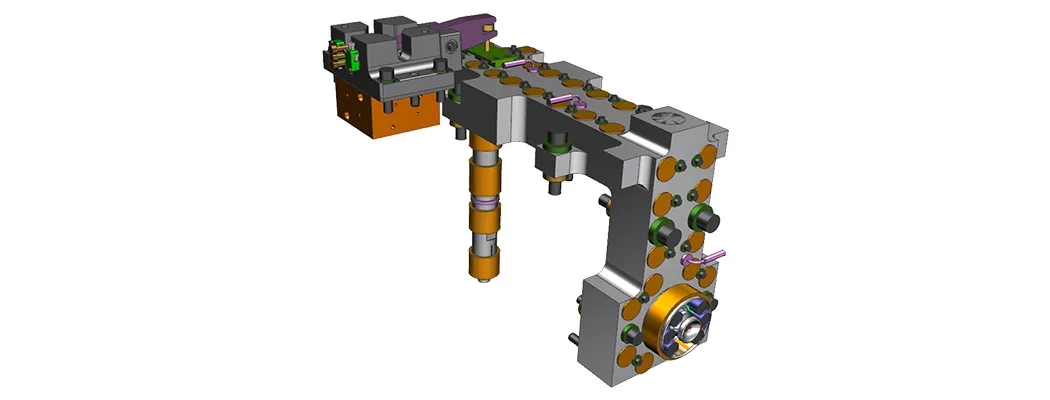

CAM TYPE

Recommended for ultra low thickness molds.

-

Optimal structure for low-type (slim/thin) molds

-

Separately mounted cylinder enables easy maintenance

-

Construction designed for strength and durability of mechanical operation.

-

High precision and durable parts ensure reliable operation

-

Complex HRB shapes, such as a diagonal L-shaped integral type, can also be manufactured.

Frequently asked questions

- What is the minimum hot runner thickness in mm?

-

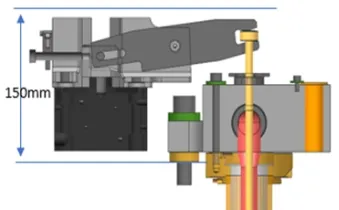

In general, the minimum thickness is approximately 150mm. (refer illustrations below.)

- Is it possible to disassemble the hot runner and cam actuation unit as one set?

-

The cylinder block is fixed on the mold side. It can be easily removed using M12 bolts.

- Is this VG durable? Does it have a track record?

-

This VG has been installed on numerous mass production molds, so you can be assured of its durability.

- In what cases would this valve gate be effective?

-

It is effective for reducing mold weight when there are restrictions on mold thickness.

- Do the valve pins in the cam structure require maintenance?

-

Periodic greasing of the pin heads is recommended to prevent damage. Fluorine-based heat-resistant grease is recommended.

- Is is possible to use conventional valve pins with this VG?

-

The valve pins are for dedicated use with cam-type VGs.

- Is is possible to use conventional cylinders with this VG?

-

The cylinders are for dedicated use with cam-type VGs.

- Is is possible to use this VG with proximity Limit Switches from conventional VGs?

-

The mechanical-type Limit Switches are for dedicated use with cam-type VGs.

TWIN WAY

Recommended for molds requiring resin color change.

-

Optimal structure for resin color switching (2 colors)

-

Structure that can be mounted on existing molding machines

-

Enables resin color switching on molding machines

-

Reduces plastic waste and man-hours required for resin color switching.

Frequently asked questions

- What is the pitch between gates in mm?

-

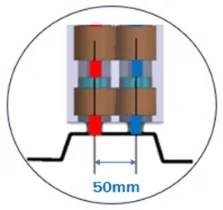

The standard dimension of the standard pitch between gates is 50mm. (refer illustrations below.)

- How many shots does it take to switch HR resin color?

-

In general, color switching can be achieved in 1 shot. Please contact a sales representative for more details.

- What mechanism is used for switching HR resin?

-

The switching block in the center is activated by a hydraulic cylinder. Please contact a sales representative for more details.

- Is this VG durable? Does it have a track record?

-

This VG has been installed on numerous mass production molds, so you can be assured of its durability.

- Can this VG be installed on small molds?

-

We also offer small-type VGs. Please contact a sales representative for more details.

- Is there an interlock mechanism?

-

Limit Switches are installed on the cylinders, so the interlock function activates when the interlock with the molding machine.

- How will the resin colors be identified?

-

It is possible to identify which color is currently being used by installing a lamp box on the mold.

- Is is necessary to increase the temperature of nozzles that are not being used for color switching?

-

In general, it is necessary to increase the temperature of the manifold, but it is not necessary to increase the temperature of nozzles that are not in use.

- Is pin opening/closing by solenoid valve required for all nozzles?

-

Solenoid valves are required for all nozzles, as even nozzles that are not in use need to be closed with pins.

- Can this VG be used with hydraulic/pneumatic cylinders?

-

Either hydraulic or pneumatic cylinder can be selected. (Hydraulic: 7 Mpa or more) (Air: 0.7 Mpa or more)

MOTOR

Recommended for molds that require optimally balanced molding.

-

Resin volume/resin flow speed can be adjusted by valve pin position and opening/closing speed.

-

Enables resin flow balancing under optimum conditions, and reduces in-mold pressure through low-pressure molding.

-

Fine-tuned parameter settings are possible.

-

No pin operation delay/time lag, thus reducing the number of defective products caused by adverse effects such as gas and slag.

-

Stabilization of production quality, i.e., reduction of defective products. And, reduction of mold clamping pressure, etc., which leads to reduction of molding equipment capacity.

-

3D TIMON resin flow analysis software can be used to find the optimum conditions.

Note: A separate fee will be charged.

Frequently asked questions

- What kind of products can this VG be used effectively used for molding?

-

Our products are effectively used to improve molding quality, improve the defect rate, promote family molding of irregularly shaped products, and reduce internal mold pressure.

- Can this VG be installed on small molds?

-

Dimensions for standard VGs and small-type VGs are also available. Please contact a sales representative for more details. (refer illustrations below.)

- What is the type of motor used in this VG?

-

The motor used is a stepping motor.

- Is it possible to conduct flow analysis of parameter, etc.?

-

Flow analysis is available as an additional option for the 3D TIMON analysis software. (additional charge applicable)

- Is this VG durable? Does it have a track record?

-

This VG has been installed on numerous mass production molds, so you can be assured of its durability.

- Is a dedicated electric controller required?

-

A dedicated electric controller for 10-point control is required separately. (Size: 512 x 1000 x 1277) with casters.

- What is the voltage required to power the electric controller?

-

Three-phase 200V (20A) or above is required.

- What kind of control is available?

-

Up to 3 steps of operation can be specified by setting numerical values for time, position, and speed on the touch panel screen from the beginning of the injection process.

- What kind of signal is required for the controller to begin operating?

-

Please output an injection start signal or a mold clamping completion signal from the molding machine. (no voltage a-contact)

- Does the dedicated controller come with a metal connector cable?

-

A dedicated cable is included. (Dedicated metal connector on the mold side not included)

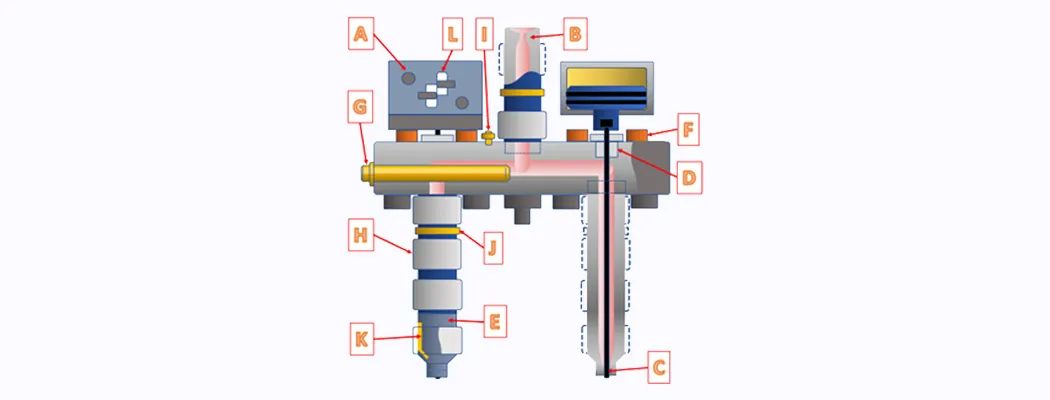

MAINTENANCE

Spare parts recommended

-

- A

- Valve heat resistant cylinder

-

- B

- Sprue bushing

-

- C

- Valve pin

-

- D

- Valve pin guide

-

- E

- Gate tip bushing

-

- F

- Thermal insulation washers (4 pcs per set)

-

- G

- Various heaters for manifold block

(The image above shows a horizontally inserted cartridge heater.)

-

- H

- Various band heaters

-

- I

- Thermocouple (In manifold block)

-

- J

- Thermocouple (On sprue bushing/extension nozzle)

-

- K

- Thermocouple (On gate bushing)

-

- L

- Heat-resistant proximity switch (OP/CL 2 pcs per set)

Providing the strength of VG made by a mold manufacturer-supert total balance of services.

-

Simple structure allowing for easy part replacement and maintenance

-

Each nozzle is integrated into the manifold block for easy disassembly from the mold.

-

Improved formability with high customizability. For example, elimination of resin flow at unused nozzles.

-

Special jigs are also available to make part replacement safer and more convenient

Frequently asked questions

- How long is the lifespan of a valve gate?

-

As with automotives, if the consumable parts are replaced appropriately, valve gates can be used for more than 10 years.

- What are consumable parts? And how many years do they need to be replaced?

-

Consumable parts can be broadly divided into the 2 following categories.

[Sliding parts] Parts that can wear out due to valve pin operation

[Electrical parts] Heaters and temperature sensors (thermocouples)

As part lifespan depends on the environment in which they are used, we are unable to provide a general answer. - Do the parts come with a warranty period?

-

Yes. Our standard warranty covers a period of 1 year or 100,000 shots following shipment from our company.

However, the product must have been used within normal parameters. - Does maintenance need to be performed frequently?

-

Although it depends on production conditions, we recommend that you perform maintenance every 3-6 months.

You can also commission us to perform regular maintenance. (However, this will be at an additional cost.) - What is regular maintenance of valve gates?

-

Regular maintenance primarily involves checks for loose mounting bolts with molds and removal of resin residue, etc.

- Are replacement parts readily available?

-

We have many standard parts in stock, including cylinders, heaters/sensors, etc.

We also recommend that you keep at least the minimum number of spares for specialized parts. - Do you have any recommendations for spare parts?

-

We can provide a list of recommended spare parts.

This list is only a recommendation and the final selection can be made by the customer.