We manufacture molds that exceed customer expectations with our advanced technical capabilities.

Using our advanced technical capabilities, we design molds in-house and manufacture them while responding to the diversifying needs of our customers. We also realize high cycle production for our customers' production lines.

Production Flow

-

Conceptual Mold Design

-

-

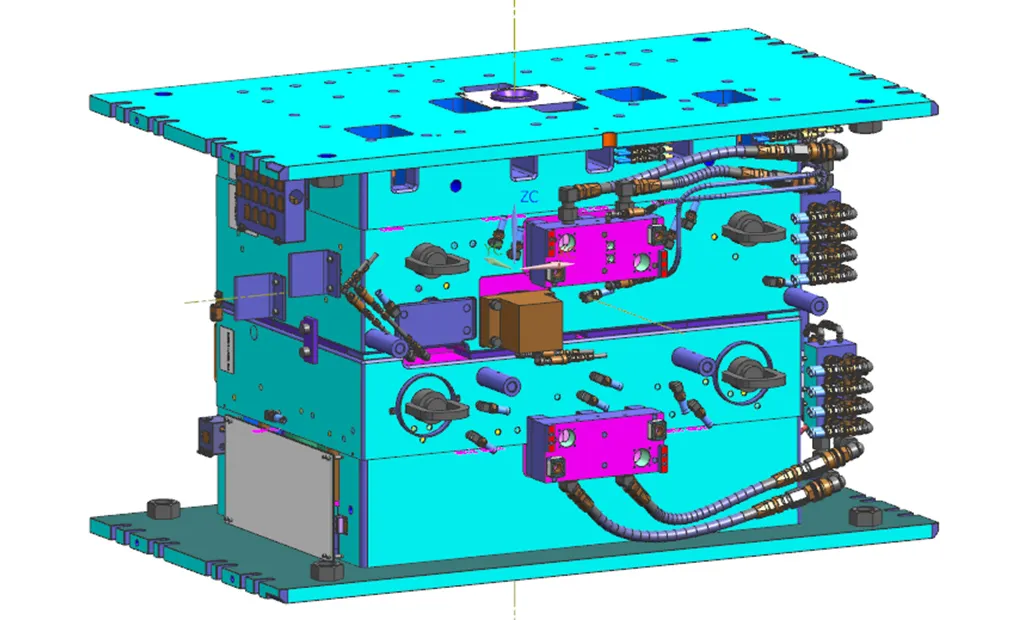

In order to manufacture molds to meet diversifying needs, we create our own design plans and create conceptual mold designs based on our customers' mold specifications and molding machine specifications.

-

Our standard and commercial components are registered as standard CAD components, and various undercut structures are also registered as units. This reduces the time required for design review.

-

-

Detailed Mold Design

-

-

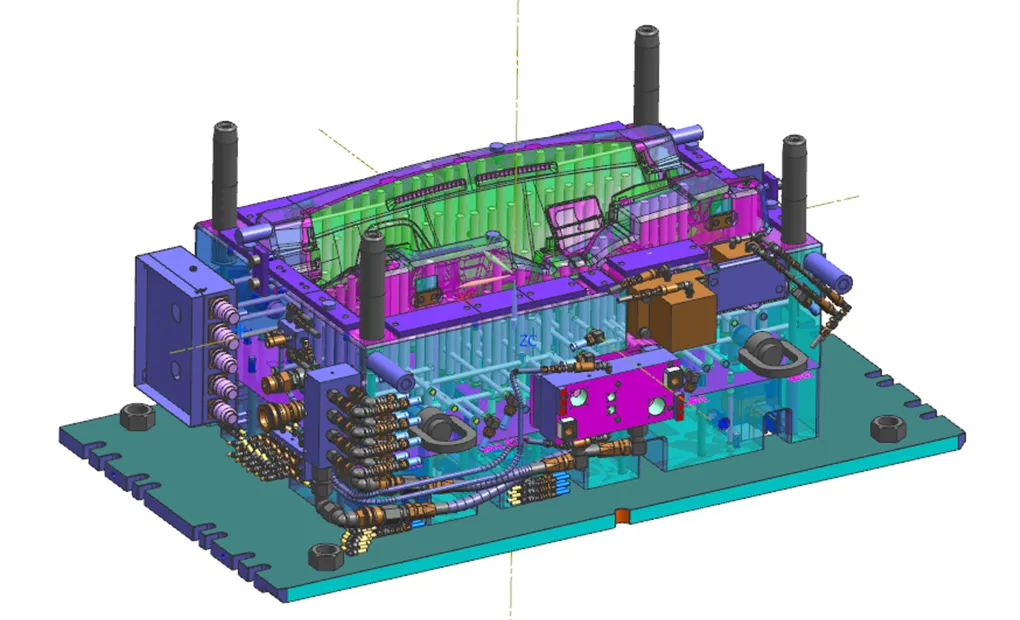

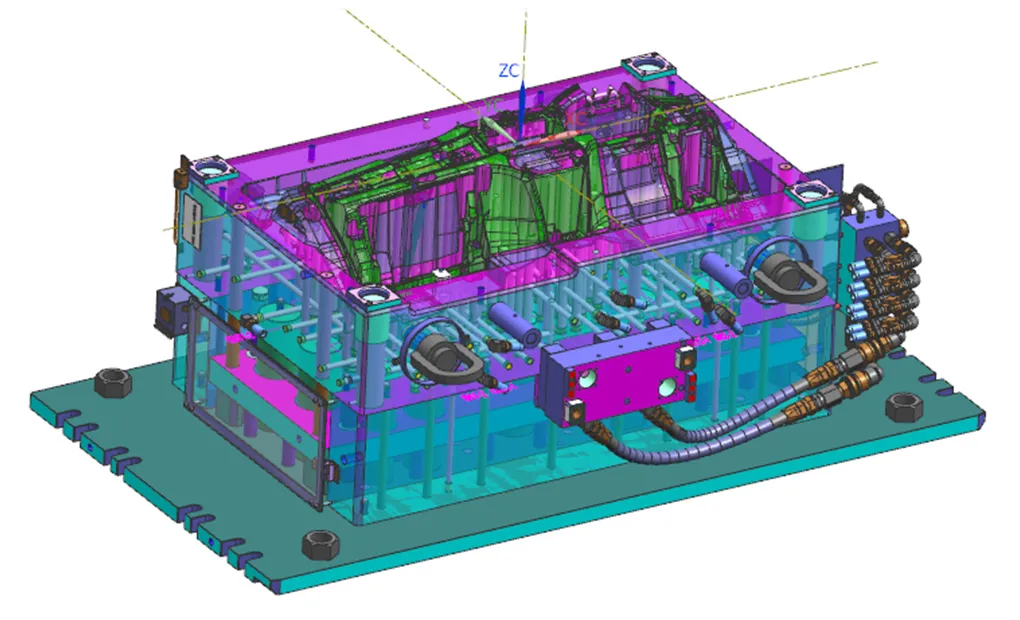

We offer optimal proposals for ejector, cooling, and Gas venting structures based on our more than 60 years of design-related technical expertise.

-

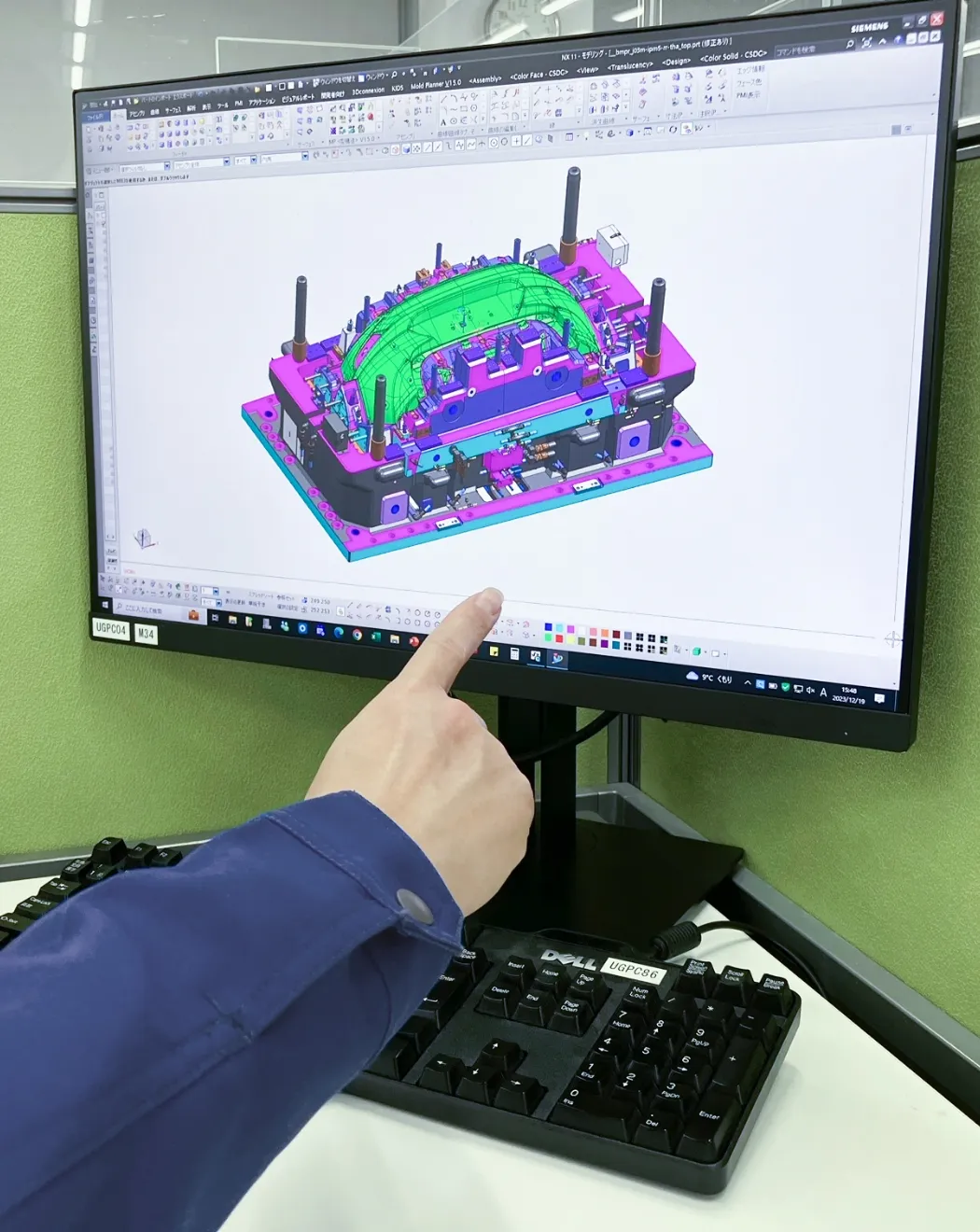

We apply 3D design for everything from basic mold structures to external view data, and output the 3D data to the machining and assembly processes.

-

Since we are able to view 3D data at our plant, machining and assembly workers are able to work while referencing 3D data.

-

We use 2D drawings of molds as outline drawings to create assembly drawings, external view drawings, bills of materials, and various wiring diagrams.

-

-

3D Solid Design

We believe that we can reduce the man-hours required for mold design and manufacturing by supplying and leveraging design data in manufacturing processes.

Applying 3D solid design to reduce design time and improve machining efficiency

-

Integrated use of data up to mold Manufacturing process

-

3D Interference Check

-

Paperless design

-

Visual decision can be made and there are few differences in individual experience.

Development of highly efficien/shorter delivery mold design and manufacturing system for plastic injection automotive parts

-

Cavity 3D -

Core 3D -

Mold external view 3D -

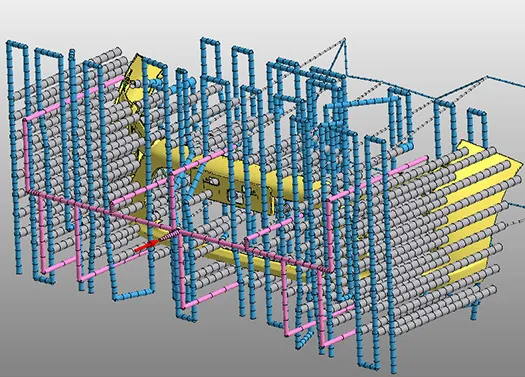

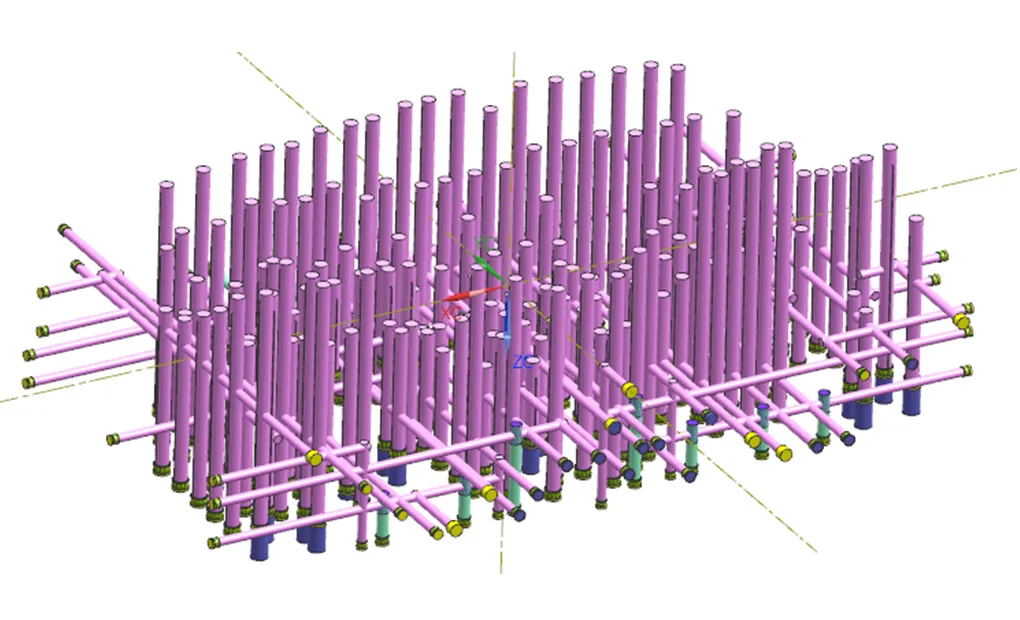

Cooling circuit arrangement -

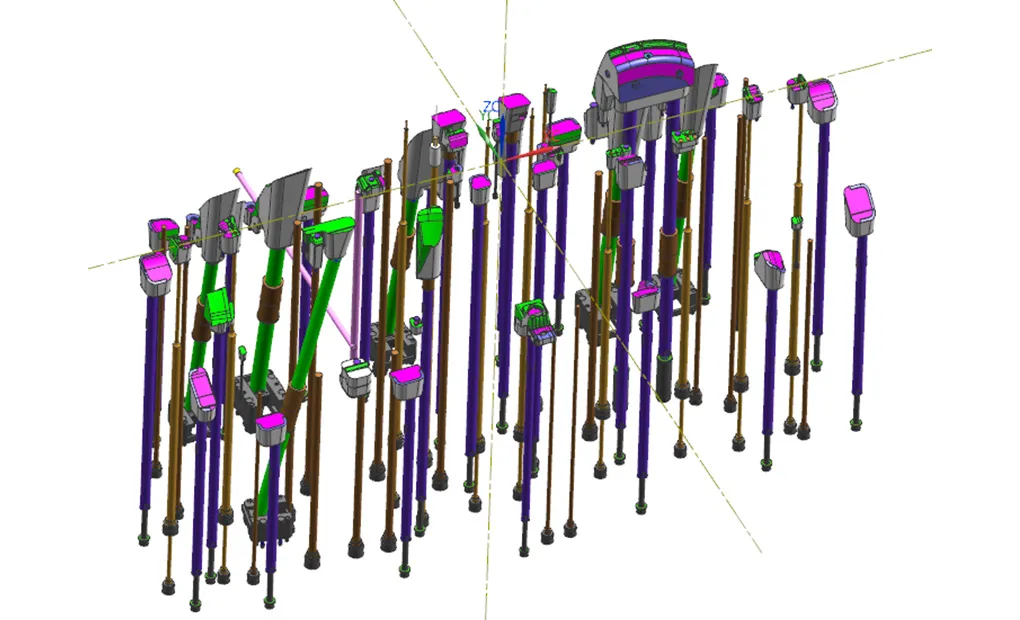

Ejection/Undercut

-

Our Approach to High Cycle

We believe that high cycle can be realized through the integration of mold manufacturing and molding technologies. We contribute to reductions in our customers' line costs through our unique expertise accumulated over many years.

We support our customers' high cycle operations with S-VANCE's unique expertise.

-

Proposing optimal cooling setups

-

Proposing optimal ejector balance by applying ejector pins and ejector blocks

-

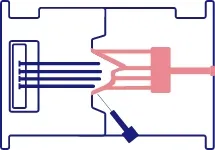

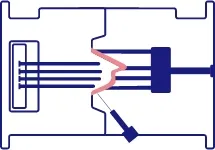

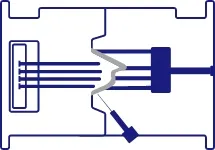

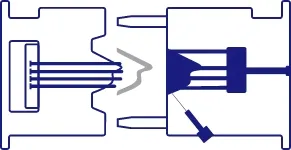

Proposing S-VANCE valve gates

-

- W

- Injection

-

- W

- Dwelling

-

- D

- Mold opening

-

- W

- Cooling

-

- D

- Take-out

-

CAE Solutions

We believe that high quality molds are realized by combining the expertise of a specialist mold manufacturer that has been accumulated over many years with CAE analysis engineering.

Leveraging CAE analysis technology

-

Realizing optimal mold design

-

Predicting defects in the initial mold flow analysis phase

-

Reduction of production preparation lead time

-

Reduction of production line costs

-

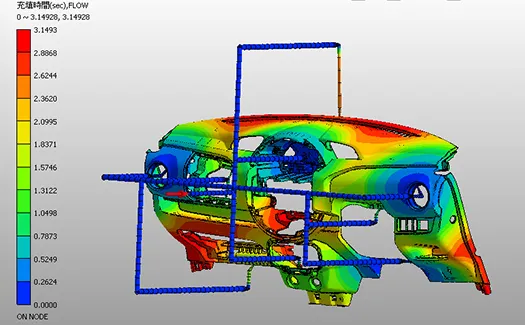

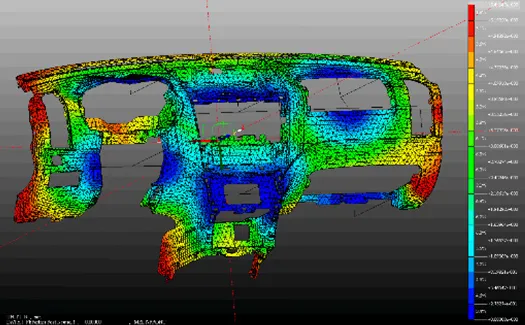

Mold Flow Analysis

Mold flow analysis enables design proposals that account for weld lines and offer optimal gate layouts.

-

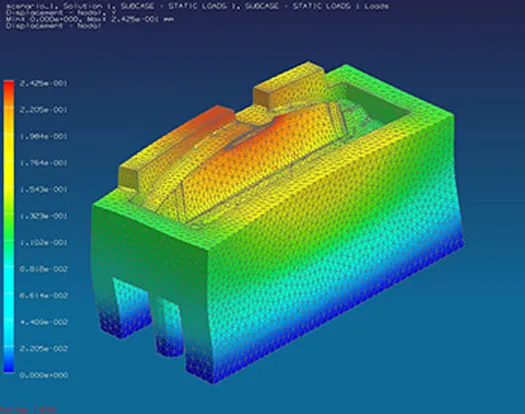

Structural Analysis

Mold structural analysis enables strength and rigidity predictions, enabling design proposals that contribute to longer mold lifespan.

-

Cooling Analysis

The simulation of mold cooling properties through mold cooling analysis enables design proposals that contribute to high-cycle molding.